Tires Tech

Tire

A tire (in American English and Canadian English) or tyre (in British English, Australian English and others) is a ring-shaped covering that fits around a wheel rim to protect it and enable better vehicle performance by providing a flexible cushion that absorbs shock while keeping the wheel in close contact with the ground. The word itself may be derived from the word “tie,” which refers to the outer steel ring part of a wooden cart wheel that ties the wood segments together (see Etymology below).

The fundamental materials of modern tires are Synthetic Rubber, Natural Rubber, Fabric, and Wire, along with other compound chemicals. They consist of a tread and a body. The tread provides traction while the body ensures support. Before rubber was invented, the first versions of tires were simply bands of metal that fitted around wooden wheels in order to prevent wear and tear. Today, the vast majority of tires are pneumatic, comprising a doughnut-shaped body of cords and wires encased in rubber and generally filled with compressed air to form an inflatable cushion. Pneumatic tires are used on many types of vehicles, such as bicycles, motorcycles, cars, trucks, earthmovers, and aircraft.

Tire Size And Measurements

How To Read A Tire’s Sidewall

Practically everything you need to know about a tire can be found on its sidewall.

How to interoperate the size of the tire.

For example: P205/55 R 16 91S

P = Passenger Car Tire

205 = Section Width in Millimeters

55 = Aspect Ratio

R = Radial Construction

16= Rim Diameter in Inches

91 = Load index

S = speed rating

Tire Anatomy And Construction

Tread :

The tread is the part of the tire that comes in contact with the road surface. The tread is a thick rubber, or rubber/composite compound formulated to provide an appropriate level of traction that does not wear away too quickly. The tread pattern is characterized by the geometrical shape of the grooves, lugs, Voids and sipes. Grooves run circumferentially around the tire, and are needed to channel away water. Lugs are that portion of the tread design that contacts the road surface. Voids are spaces between lugs that allow the lugs to flex and evacuate water. Tread patterns feature non-symmetrical (or non-uniform) lug sizes circumferentially in order to minimize noise levels at discrete frequencies. Sipes are valleys cut across the tire, usually perpendicular to the grooves, which allow the water from the grooves to escape to the sides in an effort to prevent hydroplaning.

Treads are often designed to meet specific product marketing positions. High performance tires have small void ratios to provide more rubber in contact with the road for higher traction, but may be compounded with softer rubber that provides better traction, but wears quickly. Mud and snow (M&S) tires are designed with higher void ratios to channel away rain and mud, while providing better gripping performance.

Specialized tires will always work better than general/all purpose/all weather tires when being used in the conditions the specialized tires are designed for.

Rib

Tread rib provide the contact surface necessary to provide traction. As the tread rib enters the road contact area, or footprint, it is compressed. As it rotates through the footprint it is deformed circumferentially. As it exits the footprint, it recovers to its original shape. During the deformation and recovery cycle the tire exerts variable forces into the vehicle. These forces are described as Force Variation.

Tread Block

Tread blocks provide space for the rib to flex and deform as it enters and exits the footprint. Blocks also provide channels for rainwater, mud, and snow to be channeled away from the footprint. The block ratio is the block area of the tire divided by the entire tread area. Low block areas have high contact area and therefore higher traction on clean, dry pavement.

Grooves

The groove is a design element of the tread pattern specifically arranged to channel water away from the footprint. Rain grooves are circumferential in most truck tires. Many high performance passenger tires feature rain grooves that are angled from the center toward the sides of the tire. Some tire manufacturers claim that their tread pattern is designed to actively pump water out from under the tire by the action of the tread flexing. This results in a smoother ride in different types of weather.

Sipes

Tread rib often feature small narrow blocks, or sipes, that improve the flexibility of the rib to deform as it traverses the footprint area. This reduces shear stress in the rib and reduces heat buildup. Sipes also provide greater traction in wet or icy conditions.

Shoulder

The shoulder is that part of the tire at the edge of the tread as it makes transition to the sidewall.

Cap Plies

Cap plies provide the rigid base for the tread which allows for good gas mileage. The plies also provide centrifugal and lateral rigidity to the tire, while also allowing the tire flex sufficiently for a comfortable ride.

Belts

Belts are narrow layers of coated tire cord or rubber encased steel cords located directly under the tread in the crown of the tire to resist deformation in the footprint (i.e., the tire’s contact patch on the road) to restrict the carcass plies, and to increase the puncture resistance of the tire.

Radial Plies

The radial plies are comprised of the textile fiber cables that are bonded into the rubber. These fiber cables are largely responsible for determining the strength of the tire.

Bead Chaffer

Chaffers” refers to narrow strips of material placed around the outside of the bead to protect cord plies from the rim, distribute flexing above the rim.”

Bead

The bead is that part of the tire that contacts the rim on the wheel. The bead is typically reinforced with steel wire and compounded of high strength, low flexibility rubber. The bead seats tightly against the two rims on the wheel to ensure that a tubeless tire holds air without leakage. The bead fit is tight to ensure the tire does not shift circumferentially as the wheel rotates. The width of the rim in relationship to the tire is a factor in the handling characteristics of an automobile, because the rim supports the tire’s profile.

Wear Bar

Wear bars (or wear indicators) are raised features located at the bottom of the tread grooves that indicate the tire has reached its wear limit. When the tread lugs are worn to the point that the wear bars connect across the lugs, the tires are fully worn and should be taken out of service. Most wear bars indicate a remaining tread depth of 1/16’s of an inch and are deemed “worn out” at that point.

Contact Patch

The contact patch, or footprint, of the tire, is merely the area of the tread that is in contact with the road surface. This area transmits forces between the tire and the road via friction. The length-to-width ratio of the contact patch will affect steering and cornering behavior.

Sidewall

The sidewall is that part of the tire that bridges between the tread and bead. The sidewall is largely rubber but reinforced with fabric or steel cords that provide for strength and flexibility. The sidewall transmits the torque applied by the drive axle to the tread in order to create traction. The sidewall, in conjunction with the air inflation, also supports the load of the vehicle. Sidewalls are molded with manufacturer-specific detail, government mandated warning labels, and other consumer information, and sometimes decorative ornamentation, like whitewalls.

Shoulder

The shoulder is that part of the tire at the edge of the tread as it makes transition to the sidewall.

Construction Type

Semi-Pneumatic

Semi-pneumatic tires have a hollow center, but they are not pressurized. They are light-weight, low-cost, puncture proof, and provide cushioning. These tires often come as a complete assembly with the wheel and even integral ball bearings. They are used on lawn mowers, wheelchairs, and wheelbarrows. They can also be rugged, typically used in industrial applications, and are designed to not pull off their rim under use.

Belted Bias

A belted bias tire starts with two or more bias-plies to which stabilizer belts are bonded directly beneath the tread. This construction provides smoother ride that is similar to the bias tire, while lessening rolling resistance because the belts increase tread stiffness. The plies and belts are at different angles, which improves performance compared to non-belted bias tires. The belts may be cord or steel.

Solid

Many tires used in industrial and commercial applications are non-pneumatic, and are manufactured from solid rubber and plastic compounds via molding operations. Solid tires include those used for lawn mowers, skateboards, golf carts, scooters, and many types of light industrial vehicles, carts, and trailers. One of the most common applications for solid tires is for material handling equipment (forklifts). Such tires are installed by means of a hydraulic tire press.

Bias

Bias tire (or cross ply) construction utilizes body ply cords that extend diagonally from bead to bead, usually at angles in the range of 30 to 40 degrees, with successive plies laid at opposing angles forming a crisscross pattern to which the tread is applied. The design allows the entire tire body to flex easily, providing the main advantage of this construction, a smooth ride on rough surfaces. This cushioning characteristic also causes the major disadvantages of a bias tire: increased rolling resistance and less control and traction at higher speeds.

Radial

Radial tire construction utilizes body ply cords extending from the beads and across the tread so that the cords are laid at approximately right angles to the centerline of the tread, and parallel to each other, as well as stabilizer belts directly beneath the tread. The belts may be cord or steel. The advantages of this construction include longer tread life, better steering control, and lower rolling resistance. Disadvantages of the radial tire include a harder ride at low speeds on rough roads and in the context of off-roading, decreased “self-cleaning” ability and lower grip ability at low speeds.

Tires that are hollow but are not pressurized have also been designed for automotive use, such as the tweel (a portmanteau of tire and wheel), which is an experimental tire design being developed at Michelin. The outer casing is rubber as in ordinary radial tires, but the interior has special compressible polyurethane springs to contribute to a comfortable ride. Besides the impossibility of going flat, the tires are intended to combine the comfort offered by higher-profile tires (with tall sidewalls) with the resistance to cornering forces offered by low profile tires. They have not yet been delivered for broad market use.

Tire Pressure Monitoring System

Tire pressure monitoring systems (TPMS) are electronic systems that monitor the tire pressures on individual wheels on a vehicle, and alert the driver when the pressure goes below a warning limit. There are several types of designs to monitor tire pressure. Some actually measure the air pressure, and some make indirect measurements, such as gauging when the relative size of the tire changes due to lower air pressure.

Tire Pressure Monitoring System

When referring to the purely geometrical data, a shortened form of the full notation is used. To take a common example, 195/55R16 would mean that the nominal width of the tire is approximately 195 mm at the widest point, the height of the side-wall of the tire is 55% of the width (107 mm in this example) and that the tire fits 16-inch-diameter (410 mm) wheels. The code gives a direct calculation of the theoretical diameter of the tire, and for a size shown as “T/A_W” is equal to T*A/1270+W in inches; here 195*55/1270+16 = 24.44 inches.

Less commonly used in the USA and Europe (but often in Japan for example) is a notation that indicates the full tire diameter instead of the side-wall height. To take the same example, a 16-inch wheel would have a diameter of 406 mm. Adding twice the tire height (2×107 mm) makes a total 620 mm tire diameter. Hence, a 195/55R16 tire might alternatively be labeled 195/620R16.

Whilst this is theoretically ambiguous, in practice these two notations may easily be distinguished because the height of the side-wall of an automotive tire is typically much less than the width. Hence when the height is expressed as a percentage of the width, it is almost always less than 100% (and certainly less than 200%). Conversely, vehicle tire diameters are always larger than 200 mm. Therefore, if the second number is more than 200, then it is almost certain the Japanese notation is being used-if it is less than 200 then the U.S./European notation is being used.

The diameters referred to above are the theoretical diameter of the tire. The actual diameter of a specific tire size can only be found in the TRA Yearbook or the manufacturer’s data books. Note that the tire’s cross-section and diameter are always specified when measured on a wheel of a specified width; different widths will yield different tire dimensions.

Examples

The tires on BMW Mini Cooper might be labeled: P195/55R16 85H

- P — these tires are for a passenger vehicle. However ‘P’ denotes P metric size load & speed rating changes for P tire & non-P tires.

- 195 — the nominal width of the tire is approximately 195 mm at the widest point

- 55 — indicates that the height of the sidewall of the tire is 55% of the width (107 mm)

- R — this is a radial tire

- 16 — this tire fits 16-inch-diameter (410 mm) wheels

- 85 — the load index, a maximum of 515 kg per tire in this case

- H — the speed index, this means the maximum permitted speed, here 210 km/h (130 mph).

The tires on a Hummer H1 might be labeled: 37X12.5R17LT

- 37 – the tire is 37 inches in diameter

- 12.5 – the tire has a cross section of 12.5 inches

- R – this is a radial tire

- 17 – this tire fits 17-inch-diameter (430 mm) wheels

- LT – this is a light truck tire.

Tire Load Index

The load index for any tire indicated the maximum weight that each tire is able to sustain. As you can see in the following table, the higher the tire’s Load Rating, the greater the load it can carry.

Speed Rating

In many countries, the law requires that tires must be specified, and fitted, to exceed the maximum speed of the vehicle they are mounted on, with regards to their speed rating code (except for “Temporary Use” spare tires). In the European community, tires that are not fit for a car’s or motorcycle’s particular maximum speed are illegal to mount. The sole exception are M+S tires, where a warning sticker stating the allowed maximum speed must be placed within clear sight of the driver inside the vehicle. Some manufacturers will install a speed governor if a vehicle is ordered with tires rated below the vehicle’s maximum speed.

If a tire is replaced with a lower speed rating than originally specified by the vehicle manufacturer, then this may render the vehicle insurance invalid.

Tire Load Range

The Load Range Letter on light truck tires indicates their ply rating.

There is a common misconception that there is a specific equivalence between a tire’s Load Range (or ply rating) and its inflation pressure at which it achieves its maximum load. In reality, tires of the same Load Index may require dramatically different pressures to achieve their published load ratings.

This can be seen by consulting the standards published every year by the industry standards group, the Tire and Rim Association. As an example, their 2010 Year Book shows that Load Range C tires may require 35 PSI or 55 PSI, Load Range D tires may require 50 PSI or 65 PSI, and Load Range E tires may require 65 PSI or 80 PSI to achieve their Load Index and Maximum Loads. This is also the case in the tables published by major tire makers, who do follow these TRA standards and have multiple inflation pressures for the same Load Range in the tires they sell.

It is essential to consult the guides like those just mentioned when making tire substitutions, and to read exactly what is imprinted on the sidewalls of tires. A different size of tire with the same Load Range may require a higher inflation pressure, and may fail in use if under-inflated.

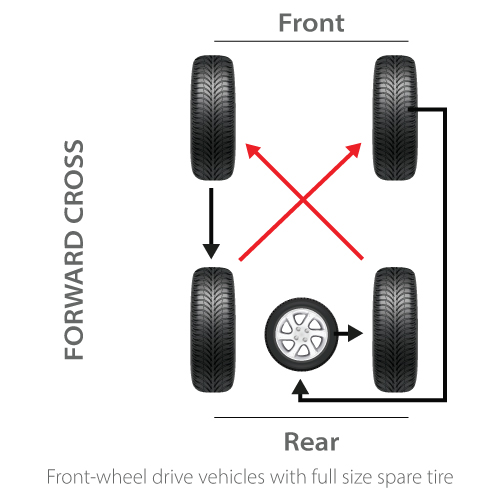

Rotation

Tires may exhibit irregular wear patterns once installed on a vehicle and partially worn. Furthermore, front-wheel drive vehicles will wear the front tires at a greater rate compared to the rears. Tire rotation is the procedure of moving tires to different car positions, such as front-to-rear, in order to even out the wear, thereby extending the life of the tire. the tires need to be rotated approximately every 5,000 to 7,000 miles.

Tire Rotation Patterns

Choosing the correct rotation pattern for your tires depends on several factors:

- If your tires are “directional” or “non-directional”

- If your vehicle is Front-Wheel-Drive (FWD) or Rear-Wheel-Drive (RWD)

- If your vehicle is Four-Wheel-Drive (4WD) or All-Wheel-Drive (AWD)

- If you have a full-size spare tire or a mini-spare

- If you have staggered fitment tires (different sizes and/or offsets on front and rear)

Non-Directional Tires, Same Size & Offset On Front & Rear

The Tire & Rim Association has identified three main rotation patterns that can be used for most vehicles in this scenario.

- Forward Cross: #1 Use this pattern if your vehicle is a FWD vehicle. Move the front tires straight back to the rear, and bring the rear tires to the opposite side of the front axle.

- Pattern: #2 If your vehicle is a FWD vehicle, you can use this as alternate pattern instead of the #1 Forward Cross. Move the front tires to the opposite rear positions and move the rear tires to the opposite front positions.

- Reward Cross: #3 Use this pattern if your vehicle is a RWD or 4WD vehicle. Move the rear tires straight up to the front and move the front tires to the opposite rear positions.

Directional Tires And/or Staggered High-Performance Tires & Wheels

In addition to the three main rotation patterns listed above, there are two additional patterns that can be used for today’s high-performance tire and wheel trends.

- Front-To-Back: #4 Directional tires are designed and constructed so that they always rotate in the same direction due to their tread pattern. If your tires are directional, they should only be rotated from front-to-back (or vice-versa) on the same side of the vehicle. If you have the same size and offset directional tires, use Pattern #4. Move the front tires to the rear on the same side and the rear tires to the front axle on the same side of the vehicle.

- Side-To-Side: #5 If you have differently-sized non-directional tires on the front and rear axles, use the side-to-side Pattern #5. Move the front tires to the opposite side of the front axle and the rear tires to the opposite rear side. If you have differently-sized directional tires on the front and rear, you cannot use Pattern #5 as shown. Instead, you will need to dismount the tires from the wheels, and remount and balance the tires on the opposite wheels.

Five Tire Rotation – Full Size Spare Tire

If your vehicle is equipped with a temporary or “mini-spare” tire, it cannot be included in your tire rotation practice. However, if your vehicle is equipped with a full size, non-directional spare tire (not branded “for temporary use”) and wheel the same size as your four main tires & wheels, you may want to consider the following rotation patterns to keep all five tires evenly worn. This is especially important for 4WD and AWD vehicles, because if you need to use your spare tire and it has different wear than your other three tires, it could place undue forces on the drive train of your vehicle due to the difference in tread depth.

Note: First, check your vehicle’s owner’s manual to see if they have a recommended tire rotation pattern and follow those

- Forward Cross For Front-Wheel-Drive: #6 If your vehicle is FWD and you have non-directional tires with a full-size matching spare, use Pattern #6. Move the rear tires to the opposite front positions. Move the left front tire to the left rear position. Move the spare tire to the right rear position and let the right front tire become the spare.

- Rearward Cross For Rear Wheel-Drive Or 4-Wheel-Drive: #7 Ifa your vehicle is RWD or 4WD with non-directional tires and a full-size matching spare, use Pattern #7. Move the left rear tire to the left front position. Move the right rear tire to the right front position. Move the right front tire to the left rear position. Move the spare tire to the right rear position and let the left front tire become the spare.

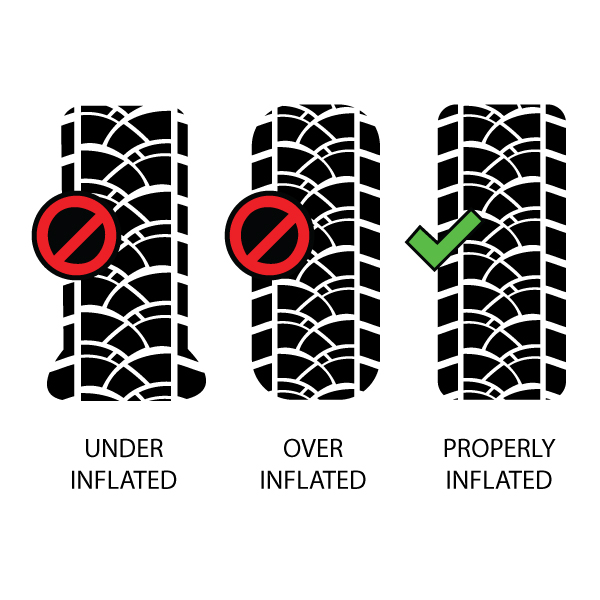

Tire Inflation

Although it may not seem to make a difference how much air is put into a tire as long as it is full and the car moves, it truly does affect many aspects of driving. Tires can be both under-inflated and over-inflated, both of which can be detrimental for proper driving.

If the tires are under-inflated, there is much more contact with the ground which slows down the car, weakens the quick responsive handling, and has limited durability and life.

On the other hand, with over-inflated tires, the contact patch is smaller and thus there is less traction as well as over-inflation weakens the structural integrity of the tire as well. It is important to always make sure that your tires are at the proper pressure and are maintained and check regularly.

Alignment

Wheel alignment is part of standard automobile maintenance that consists of adjusting the angles of the wheels so that they are set to the car maker’s specification. The purpose of these adjustments is to reduce tire wear, and to ensure that vehicle travel is straight and true (without “pulling” to one side). Alignment angles can also be altered beyond the maker’s specifications to obtain a specific handling characteristic. Motorsport and off-road applications may call for angles to be adjusted well beyond “normal” for a variety of reasons.

Primary angles

The primary angles are the basic angle alignment of the wheels relative to each other and to the car body. These adjustments are the camber, caster and toe. On some cars, not all of these can be adjusted on every wheel.

These three parameters can be further categorized into front and rear, so summarily the parameters are:

- Front: Caster (right& left)

- Front: Camber (right & left)

- Front: Toe (left, right & total)

- Rear: Camber (left & right)

- Rear: Toe (left, right & total)

- Rear: Thrust angle

Secondary angles

The secondary angles include numerous other adjustments, such as:

- SAI (left & right)

- Included angle (left & right)

- Toe out on turns (left & right)

- Maximum Turns (left & right)

- Toe curve change (left & right)

- Track width difference

- Wheel base difference

- Front ride height (left & right)

- Rear ride height (left & right)

- Frame angle

Setback (front & rear) is often referred as a wheel alignment angle. However setback simply exists because of the measuring system and does not have any specification from car manufacturers.

Measurement

A camera unit (sometimes called a “head”) is attached to a specially designed clamp which holds on to a wheel. There are usually four camera units in a wheel alignment system (a camera unit for each wheel). The camera units communicate their physical positioning with respect to other camera units to a central computer which calculates and displays how much the camber, toe and caster are misaligned.

Often with alignment equipment, these “heads” can be a large precision reflector. In this case, the alignment “tower” contains the cameras as well as arrays of LEDs. This system flashes one array of LEDs for each reflector whilst a camera centrally located in the LED array “looks for” an image of the reflectors patterned face. These cameras perform the same function as the other style of alignment equipment, yet alleviate numerous issues prone to relocating a heavy precision camera assembly on each vehicle serviced.

Tire Applications

Tires are classified into several standard types, based on the type of vehicle they serve. Since the manufacturing process, raw materials, and equipment vary according to the tire type, it is common for tire factories to specialize in one or more tire types. In most markets, factories that manufacture passenger and light truck radial tires are separate and distinct from those that make aircraft or OTR tires.

Passenger And Truck Types

High Performance

High performance tires are designed for use at higher speeds, and more often, a more “sporty” driving style. They feature a softer rubber compound for improved traction, especially on high speed cornering. The trade off of this softer rubber is shorter tread life.

High performance street tires sometimes sacrifice wet weather handling by having shallower water channels to provide more actual rubber tread surface area for dry weather performance. The ability to provide a high level of performance on both wet and dry pavement varies widely among manufacturers, and even among tire models of the same manufacturer. This is an area of active research and development, as well as marketing.

Mud and Snow

Mud and Snow, (or M+S, or M&S), is a classification for specific winter tires designed to provide improved performance under low temperature conditions, compared to all-season tires. The tread compound is usually softer than that used in tires for summer conditions, thus providing better grip on ice and snow, but wears more quickly at higher temperatures. Tires may have well above average numbers of sipes in the tread pattern to grip the ice.

Dedicated winter tires will bear the “Mountain/Snowflake Pictograph” if designated as a winter/snow tire by the American Society for Testing & Materials. Winter tires will typically also carry the designation MS, M&S, or the words MUD AND SNOW (but see All-season tires, below).Studded, highly siped, winter tire.

Some winter tires may be designed to accept the installation of metal studs for additional traction on icy roads. The studs also roughen the ice, thus providing better friction between the ice and the soft rubber in winter tires. Use of studs is regulated in most countries, and even prohibited in some locales due to the increased road wear caused by studs. Typically, studs are never used on heavier vehicles. Studded tires are used in the upper tier classes of ice racing and rallying.

Other winter tires rely on factors other than studding for traction on ice, e.g. highly porous or hydrophilic rubber that adheres to the wet film on the ice surface.

Some jurisdictions may require snow tires or tire chains on vehicles driven in certain areas during extreme weather conditions.

Mud tires are specialty tires with large, chunky tread patterns designed to bite into muddy surfaces. The large, open design also allows mud to clear quickly from between the lugs. Mud terrain tires also tend to be wider than other tires, to spread the weight of the vehicle over a greater area to prevent the vehicle from sinking too deeply into the mud. However in reasonable amounts of mud and snow, tires should be thinner. Due to them having a thinner wheel base, the tire will have more pressure on the road surface, thus allowing the tires to penetrate the snow layer and grip harder snow or road surface beneath. This does not compensate when the snow is too deep for such penetration.

All season

All-terrain tires are typically used on SUVs and light trucks. These tires often have stiffer sidewalls for greater resistance against puncture when traveling off-road, the tread pattern offers wider spacing than all-season tires to remove mud from the tread. Many tires in the all-terrain category are designed primarily for on-road use, particularly all-terrain tires that are originally sold with the vehicle.

Spare

Some vehicles carry a spare tire, already mounted on a wheel, to be used in the event of flat tire or blowout. Mini spare, or “space-saver spare” tires are smaller than normal tires to save on trunk/boot space, gas mileage, weight, and cost. Mini spares have a short life expectancy and a low speed rating (often below 60 mph).

Run-Flat

Several innovative designs have been introduced that permit tires to run safely with no air for a limited range at a limited speed. These tires typically feature strong, load-supporting sidewalls. An infamous example of an alternate run-flat technology has plastic load-bearing inserts attached to the rim instead of the reinforced sidewalls.

A disadvantage is that run-flat tires cannot be repaired if a puncture occurs, this is due to manufacturer’s informing the automotive industry that you cannot tell what kind of state the sidewall is in due to the compacted sidewall of rubber.

Racing

Racing tires are highly specialized according to vehicle and race track conditions. This classification includes tires for drag racing, Auto-x, drifting, Time Attack, Road Racing – as well as the large-market race tires for Formula One, Indy Car, NASCAR, rallying, MotoGP and the like. Tires are specially engineered for specific race tracks according to surface conditions, cornering loads, and track temperature. Racing tires often are engineered to minimum weight targets, so tires for a 500-mile race may run only 100 miles before a tire change. Some tire makers invest heavily in race tire development as part of the company’s marketing strategy and a means of advertising to attract customers.

Racing tires often are not legal for normal highway use.

Uniform Tire Quality Grading System – Treadwear – Traction – Temperature

The Uniform Tire Quality Grading System (UTQGS) is a tire information system that provides buyers with information on three categories:

- Tread-wear

- Traction

- Temperature

Each tire manufacturer performs its own tests in these areas, following government prescribed test procedures. Each manufacturer then assigns grades that are branded on the tire. This is known as the Uniform Tire Quality Grade Labeling (UTQGL).

Treadwear

The treadwear grade describes how long the tire manufacturers expects the tire to last. A Course Monitoring Tire (the standard tire that a test tire will be compared to) has a rating of “100”. If a manufacturer assigns a treadwear rating of 200 to a new tire, they are indicating that they expect the new tire to have a useful lifespan that is 200% of the life of a Course Monitoring Tire. The “test tires” are all manufacturer-dependent. Brand A’s rating of 500 is not necessarily going to give you the same mileage rating as Brand B’s tire of the same rating. The testing is non-regulated and can vary greatly. Treadwear ratings are only useful for comparing Brand A’s entire lineup against itself.

Traction

Traction grades measure the tire’s ability to stop a car in straight-ahead motion on a wet test surface pavement. It does not measure straight-ahead acceleration. It is important to remember that traction rating tests are performed only for straight-ahead sliding on concrete and asphalt surfaces that have a specified degree of wetting which simulates most road surfaces in a rainstorm. The ratings that result from these tests may not apply to cornering traction or peak values of straight-ahead braking those experienced in non-skid braking tests. Traction grades range from “A” to “C”, with “A” being the highest attainable grade.

Traction ratings are established on government maintained skid pads. Twenty measurements are taken with an industry standard control tire, on an asphalt surface, and then they are averaged. The same numbers of measurements are made on a concrete surface. Corresponding measurements are then made on the tires being tested. Once the results of the tests are compared, traction ratings based on government prescribed coefficient levels are assigned to the tires that were tested.

Temperature

Temperature grades also range from “A” to “C”, with A being the highest. Temperature grades represent a properly maintained tire’s ability to dissipate heat under controlled indoor test wheel conditions.

Temperature ratings are determined by running tires on an indoor road wheel test under specified conditions. Successive 30 minute runs are made in 5 mph increments starting at 75 mph and continuing until the tire fails. A tire is graded from “A” to “C”, with “A” being the highest.

Mismatched or Mixed Sets of Tires

In order to maintain optimum control and stability for your vehicle, you should use identical tires with the same tread pattern, size, and construction. Generally speaking, you should not use a mixed or mismatched set of tires on your vehicle unless the tire and/or vehicle manufacturer specifies that it is acceptable to do so.

Examples of mismatched tires include mixing winter and all-season or summer tires, tires with different tread patterns, tires from different manufacturers, run-flat tires with non-run-flat tires, and tires with different construction characteristics or sizes. The only exception to this would be if your vehicle has a staggered fitment with different sized tires on the front and rear axles of the vehicle.

In addition to maintaining optimum control and stability, having a uniform set of tires allows you to regularly rotate them. This will enable you to have even tire wear, thus extending their life and maximizing your investment in your tires.

Although it is ideal to have your tires wear evenly throughout their lives, it is not always possible, even with regular rotations. Tires can wear unevenly if your vehicle has staggered fitments on the front and back, if your vehicle has an alignment or other mechanical problem, if your vehicle is insufficiently maintained, or due to driving conditions. You may also lose an individual tire due to puncture or other irreparable damage. In either case, you may be forced to consider purchasing one or more tires to replace the worn and/or damaged tire(s), or having to buy a complete set and forfeiting the remaining life on the non-damaged tires.

Obviously, it is best to replace all the tires at the same time because it will restore the handling and traction to optimum levels. However, due to financial reasons, this is not always possible. On the other hand, the less-expensive alternative of replacing two of the tires requires choosing exact, equivalent, or alternative tires.

If you decide to replace just two of the tires, the best choice is to replace them with the exact same brand, style, and size as the tires already on the vehicle. This is wise because the tire’s physical dimensions, internal construction, materials, and tread design will be nearly identical to the tires you are replacing. If it is not possible to purchase the exact same tires as those currently needing to be replaced (for example, the tire is no longer available), then the next best option is to choose tires in the same performance category with equivalent load rating, speed rating, handling, and traction characteristics as the original tires. The final option of choosing alternative tires that do not match any of the characteristics of your original tires should only be used as a last resort or in an emergency situation. This is because the use of tires with different performance characteristics, load ratings, speed ratings, or sizes can cause the vehicle’s handling to become unbalanced, especially in adverse weather conditions.

In summary, always try to maintain an even set of tires that are identical in brand, model or style, size, tread pattern, and tread depth. Anything else will compromise your vehicle’s comfort, handling, and safety characteristics.